For modern dental engineering

The hyperDENT® CAM software is a completely automated programming system.

It has been specially developed for the needs of dental laboratories and dental technicians. From the automatic user interface and the undercut detection to the modern 5axis milling strategies, hyperDENT® provides innovative functions for constructing bridges simply, efficiently and precisely. The collision-free machining, even of undercuts, and the machining simulation ensure a high level of process reliability.

Highlights

Completely automated programming system

Completely automated programming systemhyperDENT® saves time and costs.

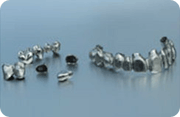

The completely automated programming system facilitates the simple and efficient production of high-quality crowns and bridges. Even users with only a little CAM experience can create milling programs quickly and reliably.

| • | Open: programming system for different data formats and many different milling machines as well as many different raw materials from several manufacturers. |  |

|---|---|---|

| • | User-friendly: clear and intuitive user interface with many practical functions for reliable and time-saving yet simple programming. | |

| • | Comprehensive: machining strategies for many different tasks – from 3D milling to sophisticated 5axis strategies – for reliable machining of even complex dental structures. | |

| • | Optimised: optional workflow manager guides the user completely automatically to the finished NC program. |

Programming

ProgrammingFinish an NC program in only a few short steps

Automatic operator guidance, a clear user interface and many fully automatic functions ensure the program is reliable and easy to use.

The use of well-known technical terms ensures fast learning. Less experienced CAM users can also create milling programs quickly and reliably in order to produce high-quality crowns and bridges. The optional workflow manager further optimises the processes by automatically guiding the user to completion of a complete NC program.

Only 8 simple steps to complete your perfect denture

Load stockThe stock is selected from a predefined list (stock management). |

|

Load objectObjects can be quickly and reliably loaded, thanks to the measuring function of the preview. |

|

Calculate toolpathsToolpaths are calculated with full collision checking and avoidance. |

|

Select milling unitMachine and holder are selected from an existing list with a click of the mouse. |

|

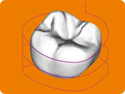

Align objectObjects are easily aligned using undercut detection. |

|

||||||||

|

|

Set sintering pinsSintering pins are moved with the mouse to the required position. |

|

Select milling strategyIt takes only one click of the mouse to assign the best machining strategy to any object. |

|

Place objectThe object can be tilted to minimise the necessary stock height. In this case, the machining occurs with fixed tool angles. |

|

Specify object propertieshyperDENT® automatically detects the tooth preparation limits. |